In this installment of Ham Mobile Install, we will talk about what happens when you have followed the mobile radio installation instructions to the letter, but there is still something very wrong with the signal.

Noise is a problem that can originate from many different sources when wiring a mobile radio. Noise is often associated with the HF bands, but it isn’t unheard of to have noise issues in VHF/UHF setups. For instance, a common complaint is vehicle alternators and certain engine types causing a whining noise on VHF radios.

Let’s look at just a couple ways hams have dealt with noise problems. If the noise is getting in through the power wires from the car battery to the radio, a quick fix could be adding some ferrite chokes. If there is still an issue, some have suggested coiling the power cable six times to form a two-inch diameter circle, and cable tying it in place. A larger ferrite choke that can fit over the loop of wire would then be added. Chokes can be added to both power cables and coax cables in case the noise is entering by that method.

Others have reported successfully eliminating noise by taking steps to improve the grounding, such as adding a common ground point for the vehicle’s body, hood, exhaust, and radios. This is usually a good practice in general.

RF signals can emanate from your vehicle ignition system, fuel pump, fans, electric motors, onboard computers, and many other sources. Spark plug noise is generated through ungrounded body panels and the exhaust system, which is normally suspended from rubber vibration dampers, as previously noted in OnAllBands. The rubberized supports insulate the exhaust from ground, essentially creating a radiating spark antenna. To deal with spark noise, use tinned copper braid to electrically connect the hood to the firewall of the vehicle. This will turn your hood into a Faraday shield.

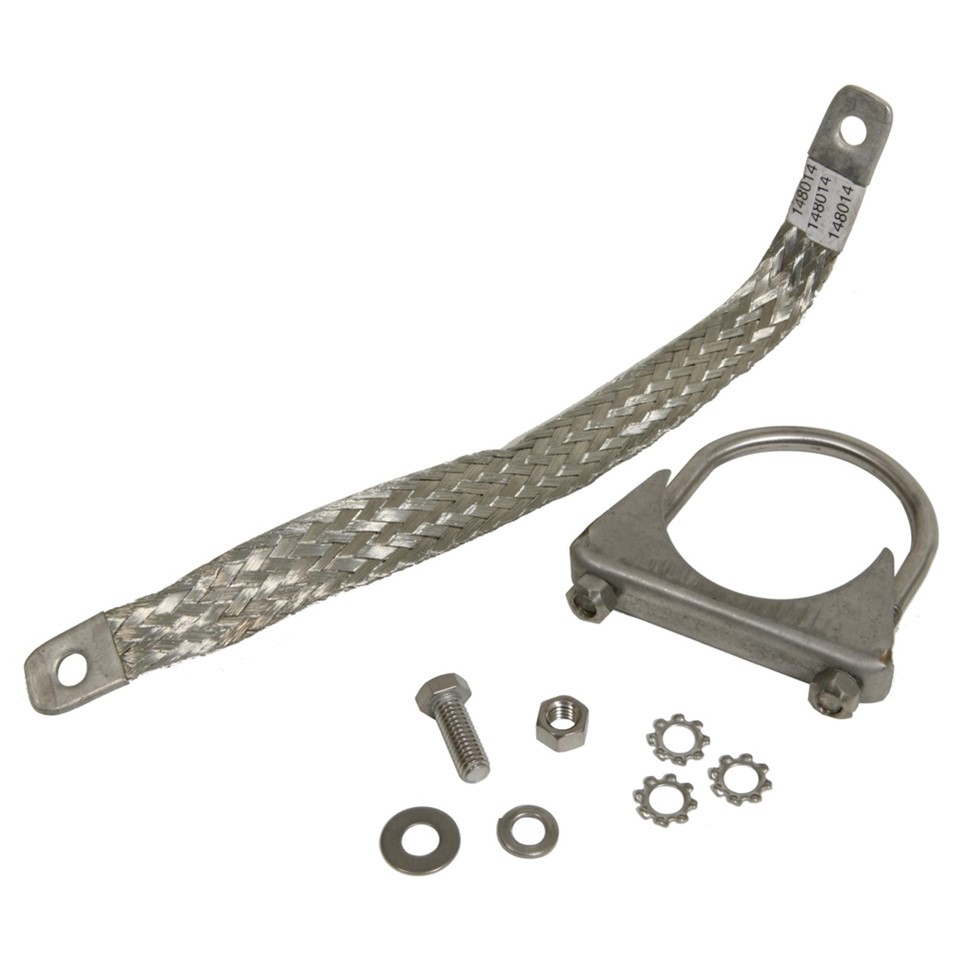

Another form of radio interference is loud static. This issue is often found on the HF frequencies, which are more susceptible to static. Bonding straps can be used for the body, hood, and exhaust to take care of a lot of these issues.

Editor’s note: DX Engineering carries a number of products designed to mitigate these mobile radio noise issues:

- Stainless steel clamps of the proper size may be used to clamp braid to the exhaust system (typically in two places—one near the front and one in the rear), thereby reducing the radiation of noise. DX Engineering DXE-TCB-050 Tinned Copper Braid is a half-inch wide and ideal for this purpose.

- For alternator noise, products like the Kenwood PG-3B Inline DC Noise Filter eliminate noise from DC supply lines in radios up to 100 watts output. As a fringe benefit, noises other than alternator noise, like that of onboard system control computers, will also be reduced. The device is connected between the supplied DC cord and your Kenwood mobile transceiver.

- If you prefer a kit that is specifically designed for exhaust grounding, try DX Engineering Exhaust Grounding Kits. These kits include pre-tinned and terminated braid with stainless exhaust clamps, along with hardware. They are available for two-inch through three-inch exhaust systems.

- DX Engineering carries ferrite RFI suppression kits, including this set of ten Mix-31 snap-on beads (DXE-CSB31-275-10), which one user singled out as “excellent for reducing noise or stray RF coming through power, speaker, or control lines, especially in mobile installations.”