All non-product graphics are used courtesy of the American Radio Relay League from the 2020 Edition of the ARRL Handbook and the referenced QST articles.

Fuses are components that “just work” until they don’t and then we have to think about them. What type of fuse is it? What is its current rating? Can I substitute a higher or lower current fuse? What if it keeps blowing?

When we build or install equipment, we also have to be sure we put the fuse in the right circuit. How do we wire a fuse holder? What special conditions apply to mobile installations? What type of fuses are used in a high-voltage supply?

So many questions for a component that seems to be no more than a piece of wire! Even so, that little piece of wire protects equipment costing hundreds or thousands of dollars and your home or vehicle, too! Let’s have a look at the different types of fuses and some guidelines for installing them. There is far too much information to cover in one article, so at the end there are a couple of useful references to help you not “blow a fuse” when working with them.

Protective Components

Fuses and their resettable companions, the circuit breakers, are called protective components. Their job is to remove power when there is a fault, such as an overload of the power source, a short circuit, or a safety hazard. The goal is to prevent fires, electrocution, and equipment damage, pretty much in that order.

Fuses are the simplest type of protective component. If the fuse’s current rating is exceeded, the “piece of wire” in the fuse, called the fusible link, heats up until it melts or “blows” and opens the circuit. (One of the definitions for “fuse” is to melt.) The heat comes from resistance in the fusible link according to I2R. There is also a small voltage drop across the fuse that increases with current, I x R. Fuses can’t be reset, just replaced. (The “resettable fuses” are components made of a polymer that changes resistance abruptly at high current. We’re not covering those here.)

Fuse Ratings

There are three primary ratings for fuses:

Nominal Current Rating—the current a fuse will carry for an indefinite period without opening. Also referred to as the fuse’s overload current, higher current is supposed to eventually cause the fuse to open.

This is the rating printed or stamped on the fuse. When you buy a “5-amp fuse,” that’s what the value refers to.

Two other ratings aren’t as well-known, but they affect the type of circuit in which a fuse should be used.

Maximum Current Interruption—how much current can be interrupted when the fuse opens. This is important when a short circuit occurs. In a vehicle’s DC power system or household AC power circuits, a short circuit can result in hundreds or thousands of amps of current.

Voltage Rating—the voltage a fuse can withstand after it opens. Fuses have different voltage ratings for AC and DC circuits. If a fuse can’t withstand the voltage present in the circuit, it will arc over and current will continue to flow. In general, the smaller the fuse, the lower its voltage rating.

Fuses for vehicle use are usually labeled “automotive” because they are intended to protect against high currents and low voltages. Household fuses are rated for 250 VAC and are physically larger than automotive fuses with the same current rating. Don’t use an automotive fuse in a circuit connected directly to the AC power line!

Types of Common Fuses

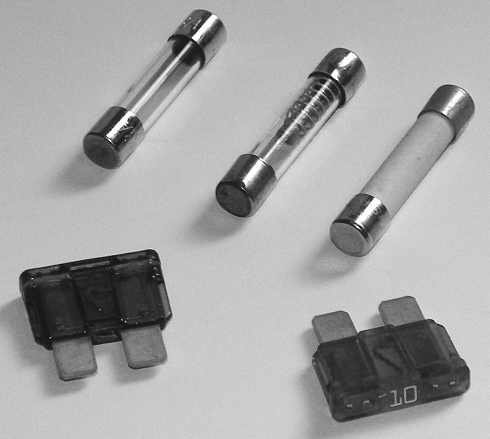

The two most common fuse package sizes are shown in the photo below. At the top of the photo are cartridge fuses in the common 3AG or AGC size (6mm ´ 32mm). When replacing cartridge fuses or buying spares, be sure you get the right size because the 5mm x 20mm size is common in equipment manufactured outside North America. These fuses are available for both AC and DC circuits.

The fuses at the bottom are blade fuses intended for use in low-voltage automotive circuits. Most have voltage ratings of 32V (AC and DC) with a few types rated for 58V. Do not use these fuses for household AC circuits!

Choosing a Fuse

You’ll find online references with a lot of information on how fuses behave under a variety of conditions. For example, what happens if the fuse is in a hot environment like an engine compartment or an amplifier? How long does it take to open under various types of overloads? Do I need a special fuse type or fuse holder? The manufacturers want you to realize the best performance from their products, so it’s worth reading what they consider to be important for product selection.

It’s worth noting that almost all commercial manufacturers specify a fuse type and size for their equipment. You should follow that recommendation! If the fuse blows repeatedly under what you consider normal conditions, it’s worth troubleshooting and finding out why—instead of just replacing it with a larger size.

The time it takes a fuse to open during an overload is also important. Fast-blow fuses will open in milliseconds during an extreme overload like a short circuit. A fast-blow glass cartridge fuse is the left-most cartridge fuse in the photo. These fuses should be selected to carry the equipment’s average current indefinitely over a wide temperature range.

Slow-blow fuses have a nominal current specification that is the same as a fast-blow fuse, but they are designed to take longer to open. That way a temporary overload or surge doesn’t blow the fuse. A slow-blow fuse would be appropriate in a power supply that can have a large turn-on current as filter capacitors charge up. The fuse element is either coiled or spring-loaded as shown in the photo’s middle cartridge fuse.

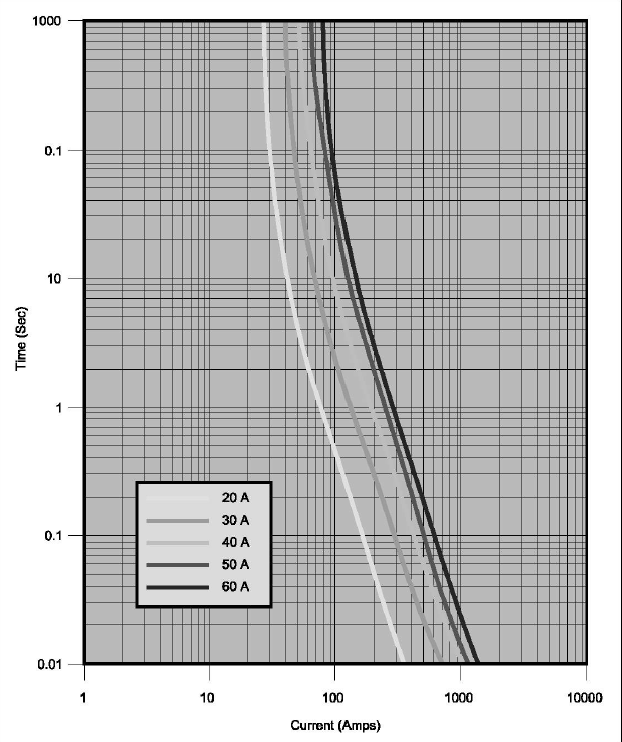

The graph above from Littelfuse is from Alan, KØBG’s QST article on fuses for mobile stations. Alan needed to pick a fuse for his 500W amplifier which draws up to 100A on voice peaks, but the average current draw was closer to 50A. The 60A Maxi fuse he chose will not open up under regular average conditions because it is rated at higher than the average current. In addition, the voice peaks are much shorter than the time it takes to blow at the peak current. But if the amplifier locks up at full power, it will blow in a few seconds. A short circuit will cause the fuse to open quickly.

Installing and Removing Fuses

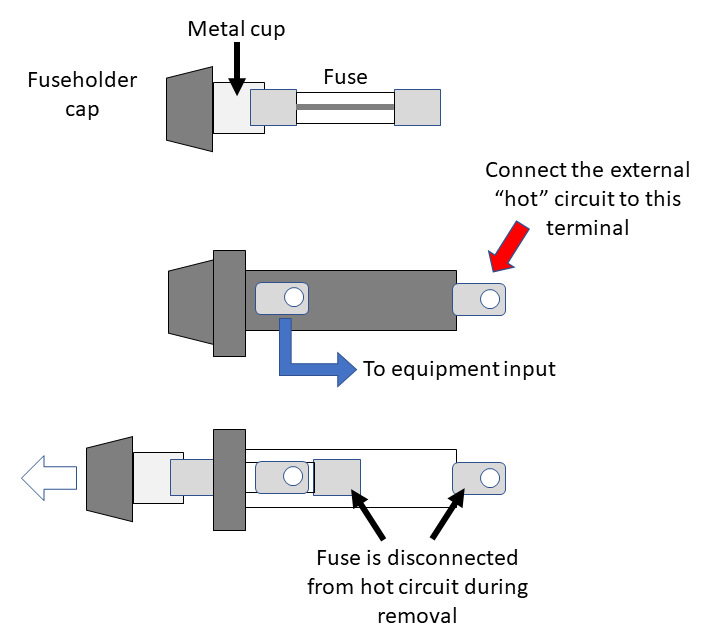

A fuse should always be installed in the “hot” power lead. (Vehicle power should be fused in both the positive and negative circuits.) Screw-in or twist-cap fuse holders for cartridge fuses should be wired so that when the fuse is being removed, it disconnects from the hot circuit before the fuse is exposed to your fingers (see graphic on disconnecting a fuse from the hot circuit). Similarly, when the fuse is being installed, the rear terminal can’t come in contact with an energized circuit while you’re holding the cap.

When using crimp terminals, such as installing them on a low-voltage fuse holder, be sure to install the terminals correctly with a proper crimping tool. Loose terminals will result in a large voltage drop during high current draw. If you are unsure of your technique, solder the terminal to the power wire.

Fuse holders and fuses must match for the fuse to be held securely, especially over wide temperature ranges. If a fuse is loose in the holder, the fuse holder won’t “close” on the fuse, or if you have to jam the fuse into the holder with a lot of force, you’re using the wrong type of fuse. If a fuse holder is forced to accept a too-large fuse, it may not hold a smaller fuse securely when the right size is installed. A loose fuse can heat up excessively from the higher contact resistance, and that will cause the fuse to open at a lower current.

When removing AC line fuses, take extra care to be sure you cannot come in contact with any live circuit. Don’t use metal screwdrivers or pliers to pull the fuse out of a holder.

Fuse pullers, like those in the photo above, are inexpensive and help get fuses out of tight spaces and holders. They are insulated so you won’t risk touching any live circuits. Automotive fuse blocks are often very tightly packed, so having a proper tool makes removing and inserting blade fuses much easier.

Fuses for Household AC Power

Most fuses for household AC current are the glass cartridge 3AG/AGC style. If you are designing and building your own equipment, you should measure the current draw under peak load and select a fuse rated for that average current level. Estimate what a “temporary overload” might consist of and review the time-to-blow charts to pick a fuse that will open if the load exceeds that level for more than a few seconds.

Always use line-rated, UL-listed fuse holders and hardware when making connections directly to the AC line. Never install fuse holders so that live voltages are exposed during normal operation. Clip-style fuse holders are only for internal installations.

High-Voltage Fuses

The body of the right-most cartridge fuse (from the photo of fuses we looked at earlier) is opaque ceramic. This is a special high-voltage fuse. Typical ratings are 600V and up to 10kA maximum current interruption. The body is ceramic to better withstand the force of a high-voltage current surge. You will find these fuses in high-voltage power supplies, such as for high-power tube RF power amps. Don’t replace these fuses with glass fuses which aren’t rated for this application. The high-voltage fuses are more expensive but are there for a reason.

Mobile DC Power and Low-Voltage Fuses

Because of the large amount of energy in a vehicle battery, it’s really important to have fuses in the power circuits of all radio equipment.

For older all-metal, welded-body vehicles, it was sufficient to put one fuse in the positive lead near the battery. Today’s vehicles mix metal and plastic parts so the chassis cannot be counted on as a negative current return path. Both positive and negative leads must be fused as a result, and most new radios come with power cables having both leads fused. (If not, add one!) The usual recommendation is to connect the negative lead directly to the battery or to the same point on the engine block where the negative terminal of the battery is connected.

Late-model vehicles incorporate a Battery Management System (BMS) that monitors current into and out of the battery to keep it fully charged. A complete discussion of where to connect power leads in a BMS-equipped vehicle and how to fuse them is beyond the scope of this article. You can find out more about the subject in the two QST articles referenced below and at KØBG’s website in the section on Wiring and Grounding.

You’ll find cartridge fuses, blade fuses, fuse holders, and electrical repair kits—which include fuses, fuse puller, and wire crimping tool—at DXEngineering.com.

Resources:

Dennis Green, KB8CS, “Fuses for the Rig in Your Vehicle,” QST, June 2007, pp. 73-74

Alan Applegate, KØBG, “Are You Using the Right Size Fuse?” QST, October 2007, pp. 30-32

Pingback: Choosing and Installing Fuses - Ham Radio News